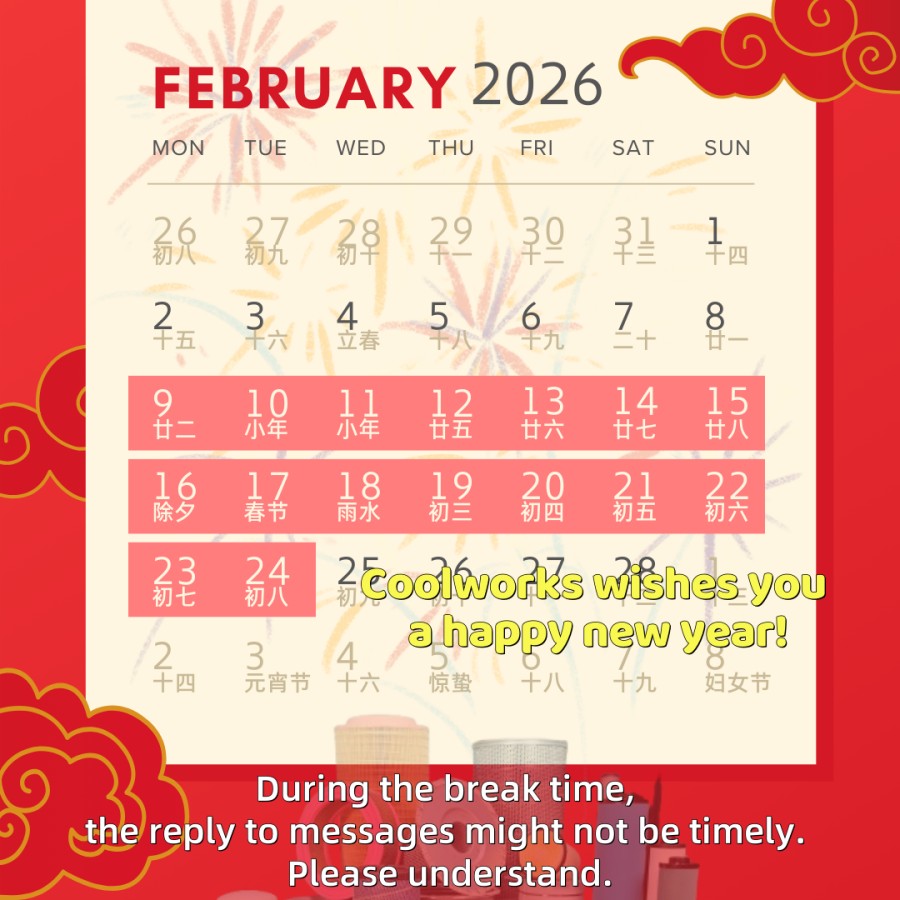

Coolworks is about to have the Spring Festival holiday. ✨We will be closed from February 9th to February 24th, 2026. ✨We will resume work on February 25th, 2026. . During the break, our responses to messages may not be as prompt. We apologize for any inconvenience this may cause. If you have any q...

Read More

English

English español

español العربية

العربية русский

русский Melayu

Melayu

IPv6 network supported

IPv6 network supported